⚙️ Keeping Count, Staying Ahead: The Smart Industrial Production Target Counter Display

In every factory, from small workshops to massive manufacturing floors, one thing matters more than anything else: meeting the daily production target.

But how do workers and supervisors know where they stand — whether they’re ahead of the game or falling behind?

Enter the Industrial Production Target Counter Display System — a simple yet powerful solution that makes targets visible, progress clear, and production smarter.

🏭 What Is a Production Target Counter Display?

Imagine a large digital display right on the factory floor. It shows:

- 🎯 The daily target (say, 500 units)

- 🔢 The current count (like 284 completed)

- ⏱️ Optionally, time left in the shift

Every time a product is finished — a sensor, button, or machine trigger updates the live count.

No need to guess. No need to ask. The numbers speak for themselves.

It motivates the team, improves transparency, and helps everyone stay on track — all in real-time.

🤖 Why This Matters in Modern Manufacturing

Here’s what makes this system a no-brainer for industries of all sizes:

✅ Real-time awareness – No surprises at the end of the day

✅ Improved teamwork – Workers know how close they are to the goal

✅ Reduced downtime – Easy to detect slowdowns early

✅ Data tracking – Great for reporting and continuous improvement

✅ Motivation – Nothing like a visible goal to spark momentum

It’s not just a number on the wall — it’s instant feedback, and feedback drives performance.

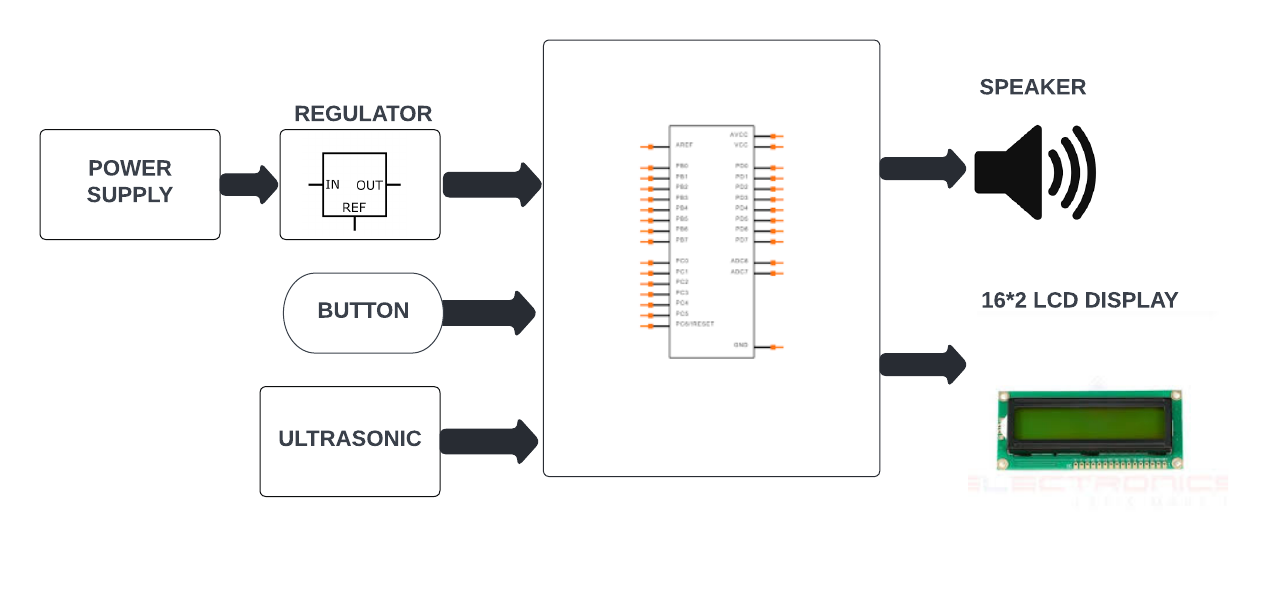

🔧 How It Works (Plain and Simple)

| Component | Role |

|---|---|

| Microcontroller (Arduino/ESP32) | Acts as the brain – counts and controls the display |

| IR/Proximity Sensor (or button) | Detects finished units or operator input |

| Display Module (7-segment/LCD/LED board) | Shows live target and actual count |

| Buzzer/Light Indicator (optional) | Alerts when target is reached or delay happens |

| Power Supply | Keeps it running 24/7 |

Optional Features:

- Wireless sync to central dashboard

- Shift-based reset timer

- Bluetooth or app-based configuration

🧪 How It’s Used on the Factory Floor

Picture this:

👷♂️ A worker finishes a part and places it on the output belt.

📟 A sensor detects it and adds +1 to the counter.

🎯 The screen now shows “Target: 500 | Done: 275”

🎉 At 500, a light blinks and a buzzer rings — goal reached!

It can even log shift data and send it to a computer or cloud for records.

🧠 What You’ll Learn (if you’re building it)

Whether you’re a student working on an industrial project or a factory owner implementing a DIY system, here’s what you’ll explore:

- Embedded systems (Arduino, Raspberry Pi)

- Sensor integration and debouncing

- Display modules (LCD, 7-segment, LED matrix)

- Shift logic and automation

- Power and enclosure design for factory conditions

💼 Real-World Benefits

This isn’t just a project — it’s a business productivity tool. Companies use it to:

- Improve time management

- Reduce supervisor workload

- Keep workers engaged with visual progress

- Optimize shift-based production

It’s like giving your factory a fitness tracker — track it, improve it.

🔮 Future Upgrades to Consider

Want to take it further?

- 🌐 Add Wi-Fi and sync data to Google Sheets

- 📱 Create a mobile dashboard for managers

- 🧠 Use AI to predict target completion rates

- 🎨 Customize the UI to show different lines or colors

From basic to brilliant, it’s up to how far you want to go!

💬 Final Thoughts: Small Device, Big Impact

Sometimes the simplest tech brings the biggest change.

A live counter display may seem small, but on the factory floor, it can mean the difference between falling behind or racing ahead.

This system empowers teams, increases efficiency, and brings clarity — one count at a time.

🚀 Want to Build or Deploy One?

Whether you’re a tech student, factory engineer, or operations manager — this system is worth trying out.

Comment below or contact us if you’d like:

- A step-by-step DIY guide

- Custom code and sensor suggestions

- Help integrating it with your existing systems

Let’s bring smart, visible progress to every production line. 🏭📈