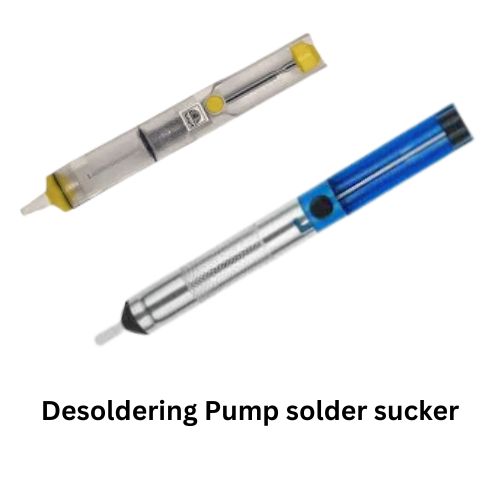

A desoldering pump (also known as a solder sucker) is a manual tool used to remove solder from a printed circuit board (PCB), especially when desoldering electronic components for repair, replacement, or recycling.

🔧 Description:

A desoldering pump typically consists of:

-

Body/Cylinder: Usually made of plastic or metal, it houses a spring-loaded piston.

-

Nozzle: A heat-resistant tip (often made of silicone or Teflon) that touches the molten solder.

-

Plunger/Button: Used to arm the spring mechanism and release it.

🛠️ How It Works:

-

Heat the solder joint with a soldering iron until the solder melts.

-

Press the plunger to load the spring in the pump.

-

Place the nozzle near or on the molten solder.

-

Press the release button—this activates the spring-loaded piston, creating a vacuum.

-

The molten solder is sucked into the pump’s chamber.

-

Empty the pump by pressing the plunger fully and shaking out the collected solder.

✅ Advantages:

-

Inexpensive and reusable.

-

Handy for through-hole component removal.

-

No electricity or batteries required.

⚠️ Tips for Use:

-

Clean the nozzle regularly to prevent clogging.

-

Use in conjunction with solder wick for better results on stubborn joints.

-

Be careful not to damage PCB pads while desoldering.

Reviews

Clear filtersThere are no reviews yet.