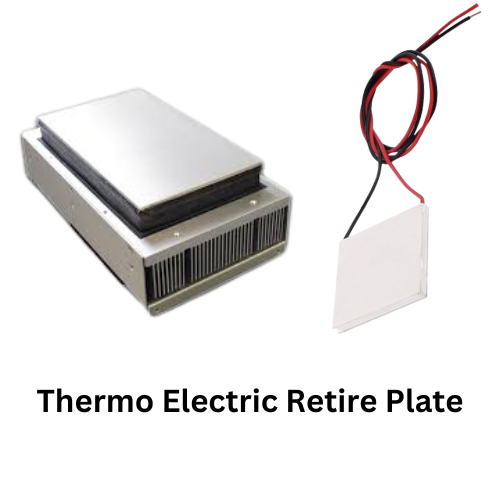

A Thermoelectric Retire Plate is typically a type of thermal management system used to dissipate heat in various applications, such as electronics, motors, or industrial systems. It utilizes thermoelectric cooling (TEC) principles to control temperature. Here’s an overview:

Working Principle:

Thermoelectric devices, including the retire plate, work on the Peltier effect, where heat is transferred from one side of the plate to the other when a voltage is applied. By using materials that conduct electricity but act as insulators to heat (semiconductors), the system can effectively transport heat away from a source.

-

Hot side: The side that absorbs heat and dissipates it to the environment.

-

Cold side: The side that remains cool by absorbing heat from the device or surface it is cooling.

Functionality of Retire Plate:

The retire plate is usually placed in direct contact with heat-sensitive components or equipment. It actively pulls heat away from the surface and directs it to the hot side, which is then cooled via air or liquid cooling.

Applications:

-

Electronics cooling: It helps in cooling chips, processors, and circuits that generate excessive heat.

-

Industrial: Used in systems requiring precise temperature control, such as sensors and machinery.

-

Laboratory: Used in scientific equipment where temperature stability is crucial.

Advantages:

-

No moving parts, hence quiet and reliable.

-

Can be used for cooling in compact spaces.

-

Offers precise temperature control.

Limitations:

-

Limited cooling capacity compared to traditional methods like fans or heat sinks.

-

Can require substantial power input for effective cooling.

-

Typically not ideal for large-scale thermal management needs due to efficiency limits.

Thermoelectric retire plates are commonly used in high-precision, small-scale applications where size, noise reduction, and temperature accuracy are critical.

Reviews

Clear filtersThere are no reviews yet.